NOVALOOP

NOVALOOP : InNOVAtive LOop For Oil Process

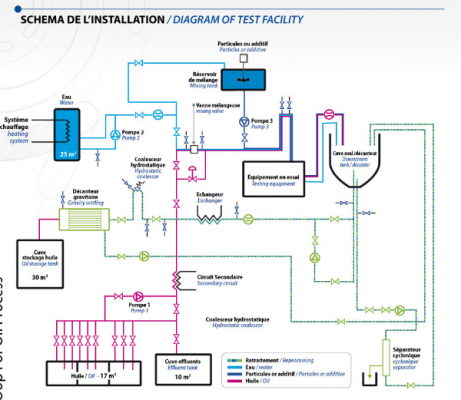

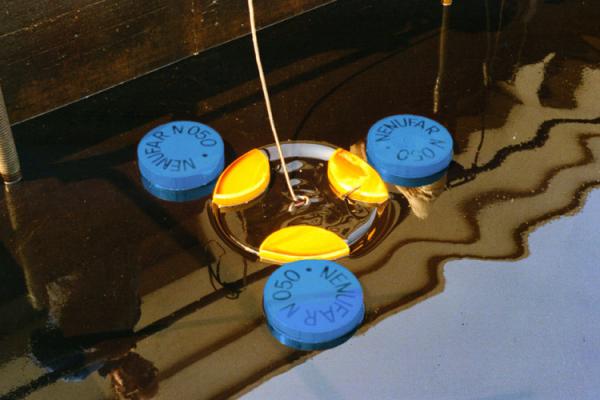

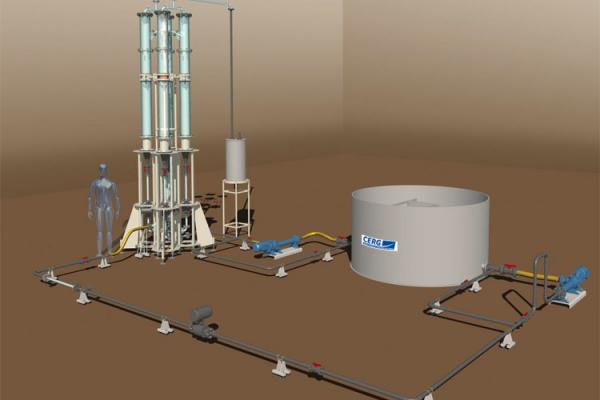

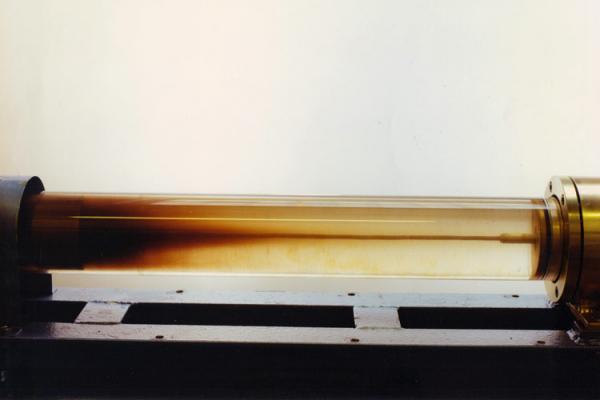

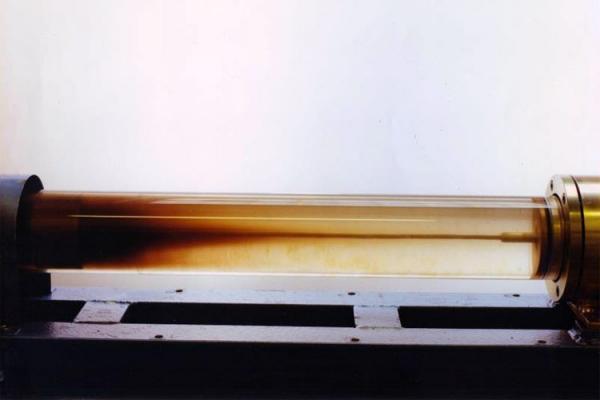

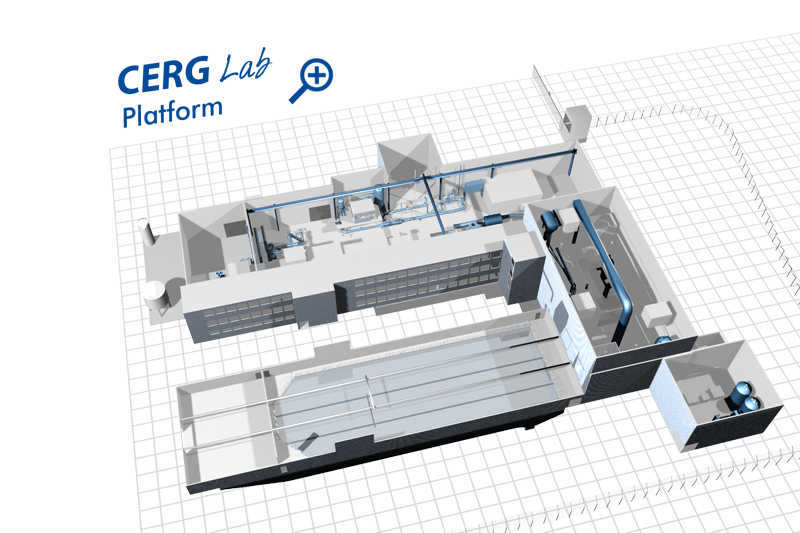

CERG's HALL 5 is dedicated to Oil & Gas processes and handles R&D projects related to oil/petroleum separation and coalescence in Subsea Process and Flow insurance programmes. There are several items of equipment: a kerosene loop for optimising fuel pumps, a loop dedicated to the power transmission lubrication, and a high temperature and high pressure cyclic pressure bench. Refurbished in 2013, it can handle future Deep Offshore and cyclonic separator projects, investigation of slugs and also sand erosion. A crude loop is available for prototype similarity studies.

IN BRIEF :

-

FLUIDS :

oil, water, kerosene, Skydroll -

FLOWRATE :

up to 50 m3/hr (0 to 210 gpm) -

PRESSURE :

up to 235 psi -

TEMPERATURES :

up to +176°F -

SPECIAL FEATURES :

ATEX, possibility of restricted access, floor area 150m² (495 ft square)

Coalescence | Flocculation | Separation | Rotating Cyclone | Emulsion | Multiphase | Similarity | Subsea Process | Deep Offshore | Slugs | Watercut | OiW Oil in Water | WiO Water in Oil |

FOLLOW US